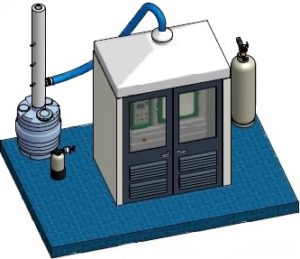

Kesternich Corrosion Chamber – SO2

The corrosion chambers type SO2, KEQ series, also known as Kesternich chamber, were built to meet the requirements of ASTM, DIN, DIN EN ISO, others.

The following construction characteristics of the equipment are very important for repeatability and reproducibility of each test, These tests are comparative, so they must follow the exact construction characteristics of the standards.

– Angled lid/ceiling with a smooth internal finish to avoid dripping on the samples.

– SD Card, saved in real time test parameters, just open Microsoft Excel to display the chart of every cycle, only KEQ 300.

– Construction according to UL508.

– All components used are UL listed.

– Internal volume of 300 liters of usable space.

– Equipment is constructed with inert materials that do not interfere in the final result of the test.

– Touch Screen

– SO2 dose controller, electronic, allowing dosages 25 ml up to 6000 ml.

Application:

The chambers are used to perform rapid acid and wet acid corrosion tests on metal parts with organic or inorganic coatings.

Its application primarily serves companies in the automotive, civil construction, plastic, aviation, oil and gas, paints, varnishes, electronics, chemical, metallurgical and other related industries.

Operation:

The test samples are arranged within the test cabinet according to technical standards. They are exposed to an acidic atmosphere (H2SO4) and wet at a temperature of 40°C for 8 hours and then enter a cooling mode with circulating air controlled for 16 hours where the internal temperature of the chamber will reach the ambient temperature of the laboratory. We usually recommend a laboratory temperature of 23°C +/- 3°C. This 24-hour period is called the round (end of the test). Normally the number of rounds should be agreed upon between the customer / supplier.

Main test standards:

ASTM G 87 – DIN 50018 – DIN EN ISO 6988-2 – ISO 3231.

VW Corporate Rules – Mercedes Benz – other consult us.