The construction of the Gravelometer equipment for the standards ASTM/SAE is completely

different when comparing to standards DIN/ISO/VDA. Taking a look at the details above, you will

realize that in order to make all in the same equipment, user must switch most of the components of

the equipment, and furthermore, be capable of adjusting and calibrating equipment every time

components are switched to avoid any leaks, if this is not accomplished correctly, it will interfere in

the results of the test. In conclusion, making both ASTM/SAE and DIN/ISO/VDA in the same equipment

is completely is impracticable, that’s why Equilam provides both standards in two different

equipment.

The construction of the Gravelometer equipment for the standards ASTM/SAE is completely

different when comparing to standards DIN/ISO/VDA. Taking a look at the details above, you will

realize that in order to make all in the same equipment, user must switch most of the components of

the equipment, and furthermore, be capable of adjusting and calibrating equipment every time

components are switched to avoid any leaks, if this is not accomplished correctly, it will interfere in

the results of the test. In conclusion, making both ASTM/SAE and DIN/ISO/VDA in the same equipment

is completely is impracticable, that’s why Equilam provides both standards in two different

equipment.

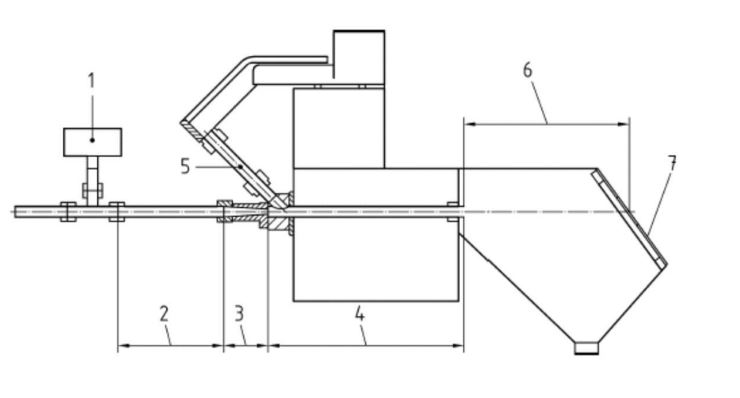

DIN 55996-1 / ISO 20567-1 / VDA:

- Gravel falls in a 54° angle into attack tube

- Air pushes gravels towards specimen which is in a 54° angle

- The distance until gravel hits specimen is 64.2cm

- Air accelerating nozzle is in a cone format with an inlet diameter of

- 19mm and outlet 7mm

- Attack tube diameter is 30mm

- Maximum air pressure is 400kPa